Metals & Mining

Maximize process efficiency, keep your equipment operational, and safeguard your staff.

Strategic support from PML will achieve safer, smarter, and more sustainable operations.

Those goals are important and crucial. PML can be your strategic partner through your digital transformation to stay competitive in the marketplace. Our team of experts will work hands-on with you to understand your specific challenges and help you unlock more efficient and productive mining operations. Let’s implement solutions that help you achieve net zero emissions, zero unplanned downtime, zero recordable safety incidents, and zero inefficiencies in your mining operations.

Solutions For Metals & Mining Operations

Mining & Ore Handling

Comminution & Concentration

Hydrometallurgy & Pyrometallurgy

Mine Tailings & Waste

Sustainability

Asset Reliability

Production Optimization

Risk Reduction

Remote Operations

SAFE & RELIABLE SOLUTIONS

Mining & Ore Handling

Whatever you need to focus on, PML can avoid delays or operational failures by using proven automation technology. Advanced automation and condition monitoring solutions can optimize your mobile assets through edge control and analytics to improve machine performance of stacker reclaimers, conveyors, crushers, optimize crushing circuit performance and track energy consumption.

Better data connectivity and analysis lead immediately to improved operational uptime and asset utilization. You use many instruments, valves, pumps, and motor controls… With the right instrumentation and edge computing, all these devices can transmit valuable machine health monitoring information to a supervisory asset management system where you can ensure instrument calibrations are up to date, confirm instruments and valves are healthy, and identify issues to order replacements or plan shutdowns.

PROCESS EFFICIENCY & ASSET MONITORING

Comminution & Concentration

Metal and mining operations face common challenges but with unique variables like the rising cost of development, volatile prices, and skilled labor shortages. With PML service and support solutions you can have your operation perform the most efficiently, reliably, and safely. We have the industry experience and local service options to help you advance your operations, automate processes, and have better control of grinding, milling, and flotation.

MAIMIZE RECOVERY & GRADE

Hydrometallurgy & Pyrometallurgy

With PML solutions, you can maximize recovery and grade with precision measurement and control solutions. And these days, you need to do more with less and still maintain asset availability. Easy-to-operate condition monitoring solution delivers the earliest detection of impending faults so you can make fast, accurate repair decisions before unplanned downtime occurs, thereby optimizing your maintenance labor costs and simplifying operator training.

ENSURE INTEGRITY OF PIPELINES & DAMS

Mine Tailings & Waste

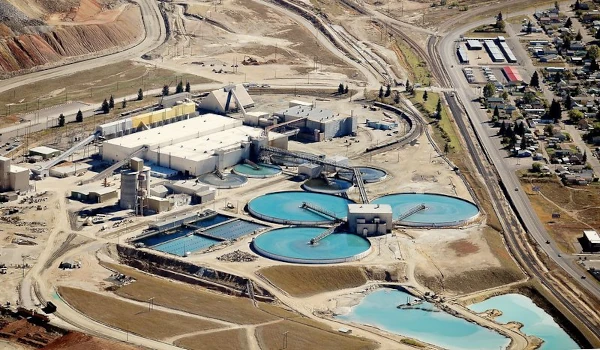

Improve safety and reliability with wireless instrumentation solutions for tailings dam monitoring and advanced flowmeters, valves, and actuators for mining slurry flow control.

Thickener performance optimization is critical to operations, but slurry flow management can be hindered for many reasons. PML’s mining slurry flow management solutions incorporate advanced flowmeters, valves, and actuators to provide accurate flow measurements and increased capacity to isolate valves in thick paste applications.

Tailings dams are only as good as their original design, so a tailings dam monitoring system that gives you visibility into dam levels and subsurface elements is crucial to your dam integrity. And while tailings risk will not impact your mining operation, a collapsed tailings dam can destroy the mine’s value, as well as a company’s reputation and license to operate.

Our experts can guide you in selecting wireless solutions to ensure safe and compliant management of your tailings dams.

MEET REGULATORY STANDARDS

Sustainability

Fueling your processes is never easy in your efforts to establish more sustainable operations, nor is it easy on your bottom line. Costs to accomplish that will not go down unless you transform the way you operate. PML’s experts can help you leverage new technology to improve efficiency, optimize water usage, and achieve a lower carbon footprint. We can work with you to minimize energy and water use to meet regulatory standards.

DeltaV Advanced Process Control

Get the most from your operations with the DeltaV distributed control system that delivers superior control through embedded advanced control applications. The control power translates to fewer engineering hours and more effective operations.

Optimize Hydrocyclone Separation Processes

Roping and plugging are common upset conditions that hinder the effective operation of your hydrocyclones. The team at PML knows how this control and optimization application addresses the problems associated with roping, plugging, and undesired particle classification. It characterizes the different operating parameters of each cyclone. Having this information per cyclone allows the execution of efficient control strategies.

INCREASE ASSET UTILIZATION

Asset Reliability

Today, every operation must do more with less while maintaining asset availability. We all need to streamline maintenance time and costs while increasing asset utilization. PML’s expertise and asset performance management solutions can aggregate real time information to mitigate unplanned downtime, predict equipment repair, optimize expensive inventories, and streamline work order practices.

Improving Mining Critical Asset Performance

Ddrive improvements in safety and reliability with real-time insight in the health of your critical mining assets. Additional sensors provide early indication of asset performance issues, and the use of preconfigured applications that use machine learning algorithms can continuously analyze process data to alert decision makers to act before failures occur.

Explore Analytics & Machine Learning Software

Most plants generate vast amounts of data, but making sense of that data requires Plantweb’s robust portfolio of scalable analytical tools to transforms plant data into actionable information. By leveraging deep domain expertise, these tools generate new operational insights that drive more effective decisions when it comes to specific asset classes or site-wide improvements.

MAXIMIZE MINERAL RECOVERY & THROUGHPUT

Production Optimization

How can you performing optimally to maximize mineral recovery and process throughput in the most cost-effective way? PML’s team of experts can help you identify opportunities to improve your recovery processes and implement an advanced control strategy that optimizes your entire mine/mill circuit from ore face to loadout.

Automate and Optimize Copper Heap Leaching Processes

There are a number of critical factors that affect the performance of a heap leaching system. The most important is properly sizing the ore. Next to proper ore sizing, leach solution distribution has the largest effect on mineral recovery. PML has worked with a number of miners to implement systems that can detect problems with emitters and improve irrigation and recovery.

Built-In Advanced Control Applications

DeltaV Advanced Control is a full suite of embedded applications that improves performance and quality, reduces waste and pollution, and minimizes operating costs. DeltaV Advanced Control and SmartProcess applications can improve plant performance using model predictive control, loop monitoring and adaptive tuning, quality prediction, and constrained optimization.

ON-GUARD SAFETY & SOCIAL RESPONSILITY

Risk Reduction

You need to take every precaution to keep your personnel out of harm’s way while also making sure to keep the environment and those surrounding the operation safe as well. PML’s experts can help you deploy technology to help you ensure the safety of your personnel and mitigate site incidents to ease your safety concerns and pursue social responsibility.

Improving Mining Personnel Safety Performance

Over and under pressurization of your tanks can cause tank collapse or implosion without a proper management plan in place. Protect your workforce and assets with our multi-layered pressure protection approach that encompasses a full spectrum of safety and environmental protection equipment and expertise.

Corrosion Erosion Monitoring for Safer More Profitable Operations

PML’s non-intrusive systems use unique sensor technology and wireless data delivery to continuously monitor for metal loss from corrosion or erosion in the most difficult environments for better-informed operational decision making and enable safer, more profitable operations.

TECHNOLOGY & TOOLS

Remote Operations

Your mine needs to run smoothly and economically if you are going to sustain a successful operation throughout cycles. Amid a volatile business landscape, you have to get every bit of productivity from all of your running assets. This means that you’ve got to prevent breakdowns whenever possible because unplanned downtime can mean expensive last-minute repairs and replacements—alongside slowed production, personnel safety concerns, and reduced profitability. To sustain success in the future, you have to do more with less.

Get Reliable Asset Data Anywhere, Anytime

To reach your mine production goals consistently depends on the ability of your maintenance staff to continuously monitor your fixed and mobile assets. Manual checks are time-consuming and costly and could put your people in hazardous situations. PML’s automated condition and asset monitoring solutions can provide accurate and reliable asset data from anywhere inside or outside your operation, keeping your people safe from harm and your goals still within reach.